Professor Alexander Salenikovich participated in WCTE 2023 in Oslo

Professor Salenikovich participated in the WCTE 2023 congress held from June 19 to 22, 2023 in Oslo, Norway, to present his research work on glued-in rods. He made two presentations and co-authored two other articles with international colleagues. The proceedings of the congress can be downloaded free of charge here.

Professor Salenikovich participated in the WCTE 2023 congress held from June 19 to 22, 2023 in Oslo, Norway, to present his research work on glued-in rods. He made two presentations and co-authored two other articles with international colleagues. The proceedings of the congress can be downloaded free of charge here.

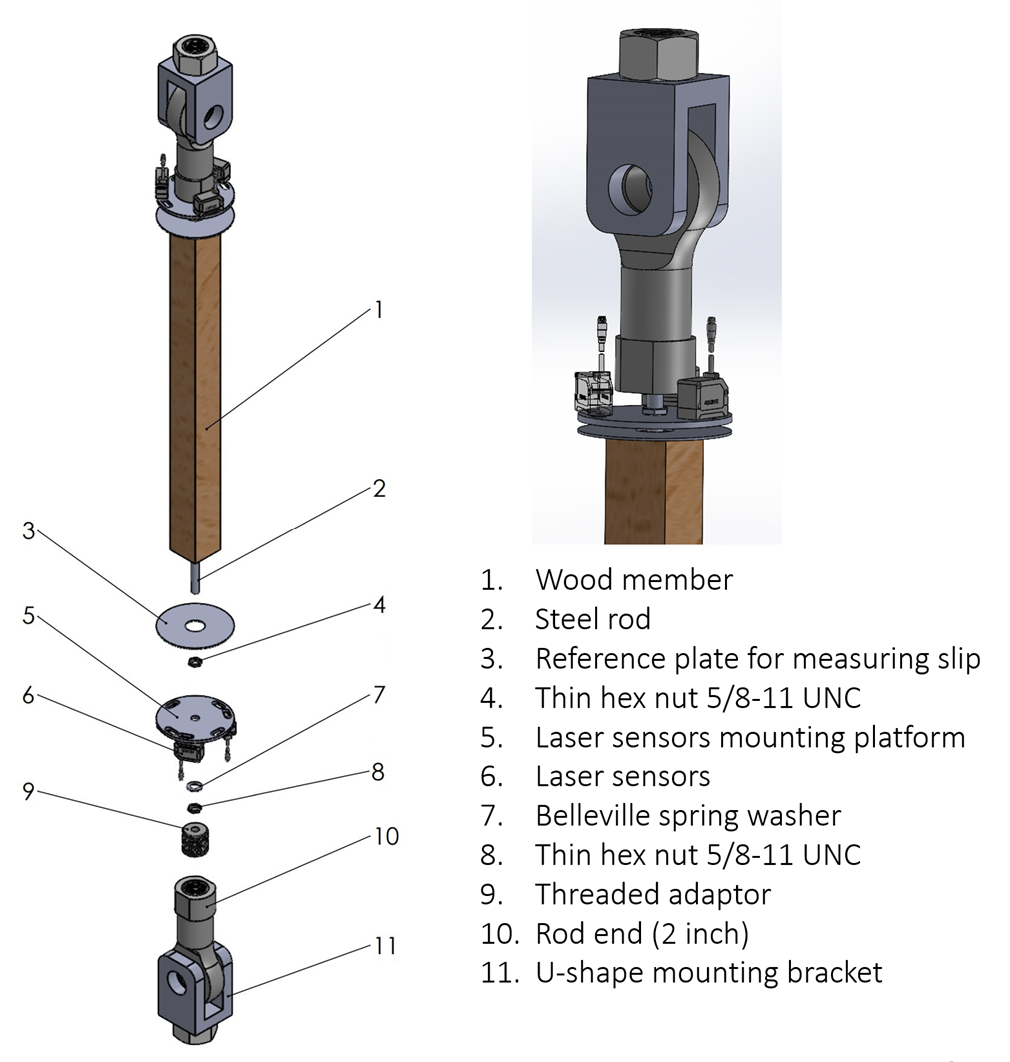

The first article was co-authored with Étienne Lapointe, an undergraduate student in wood engineering, as well as with his Swiss colleagues from GSA Technology and ASPECT Structural Engineers and an American colleague. The test device was developed and manufactured with the help of CRMR technicians Félix Pednault and Jean Ouellet (see figure below). The tests were carried out at FPInnovations. This work facilitated the development of AC526 of ICC ES «Acceptance criteria for factory installed glued-in rods in wood structural elements».

Testing device

The article is entitled «Performance of glued-in rods in glulam and MPP in tension and compression».

Abstract: This paper is focused on evaluation of the performance of glued-in rods (GIR) in Douglas-fir glulam timber and Mass Ply Panels (MPP) produced in the USA for structural applications. One of the objectives of the study was to compare the performance of GIR joints with and without recess of the bond length in tension and compression. High-strength steel threaded rods of 15.9 mm in diameter were bonded into wood members of 70 mm × 70 mm in cross-section in three configurations. In one configuration, the bond length was 20 times the stress diameter (ds) of the rod. In another configuration, the embedded length of the rod included a machined portion (constriction zone) near the end of the wood member, which created a recess (not bonded length) of 4d, while the bond length remained the same (20ds). In the third configuration, the bond length was 24ds without a recess. Test results clearly demonstrated the benefits of a recess in GIR joints to increase the structural efficiency of timber connections. No GIR buckling was observed in compression tests.

The second presentation was made on behalf of his colleagues from Moscow, Russian Federation on « Rigid joints with inclined glued-in rods for elements in bending and combined bending and compression in large-span glued-laminated timber structures»

Abstract: The construction of large-span glued-laminated (glulam) timber structures featuring long and curved elements, such as arches, portal frames, and radial ribs of domes, poses significant challenges in terms of manufacturing and transportation. One practical solution to this problem is to subdivide the structural elements into components with moment-resisting rigid joints assembled on-site. In Russia, the TSNIISK System has been developed to address this challenge, which utilizes inclined glued-in rods with anchor plates. This system features two types of rigid joints: those with unidirectional inclined glued-in rods and those with glued-in rods forming V-shaped anchors. A design methodology for the TSNIISK System has been developed, validated by control tests, and included in Russian design standards. Hundreds of timber buildings and structures have been constructed in Russia and neighbouring countries using this system, proving its effectiveness in constructing large-span timber structures with curved elements. Its implementation has significantly reduced transportation and manufacturing difficulties while ensuring the structural integrity and reliability of the structures.

Erection of 99.9 m span arches with glued-in rods for the Yenisei Ice Arena (Krasnoyarsk, RF)

The third article was co-edited with Steffen and Bettina Franke from Bern University of Applied Sciences (Switzerland) and is entitled «Bonded-in rods in beech wood – efficiency of a recess in the bondline».

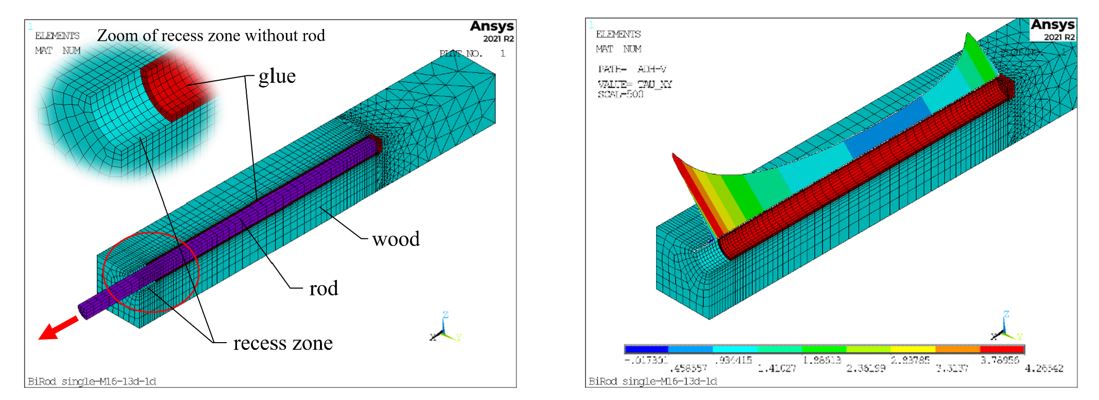

Abstract: The load-bearing behaviour of bonded-in steel threaded rods (BiR) in hardwood was investigated with special focus on the prevention of the splitting behaviour using a recess (not bonded zone) in the bondline. The main objective was to analyse the influence of the not-bonded length and the rod edge distance on the distribution of longitudinal shear and transverse tensile stresses in joints with bonded-in rods in beech glulam. Several BiR joint configurations were tested experimentally and a wide range of joint configurations with various combinations of recess and bonded lengths and edge distances were numerically investigated. According to the experimental and numerical analyses, a recess length of 3d produced a significant positive effect on the stress distribution reducing the risk of splitting of beech wood glulam in the studied joint configurations.

Finite-element model and shear stress distribution in a joint with bonded-in rod

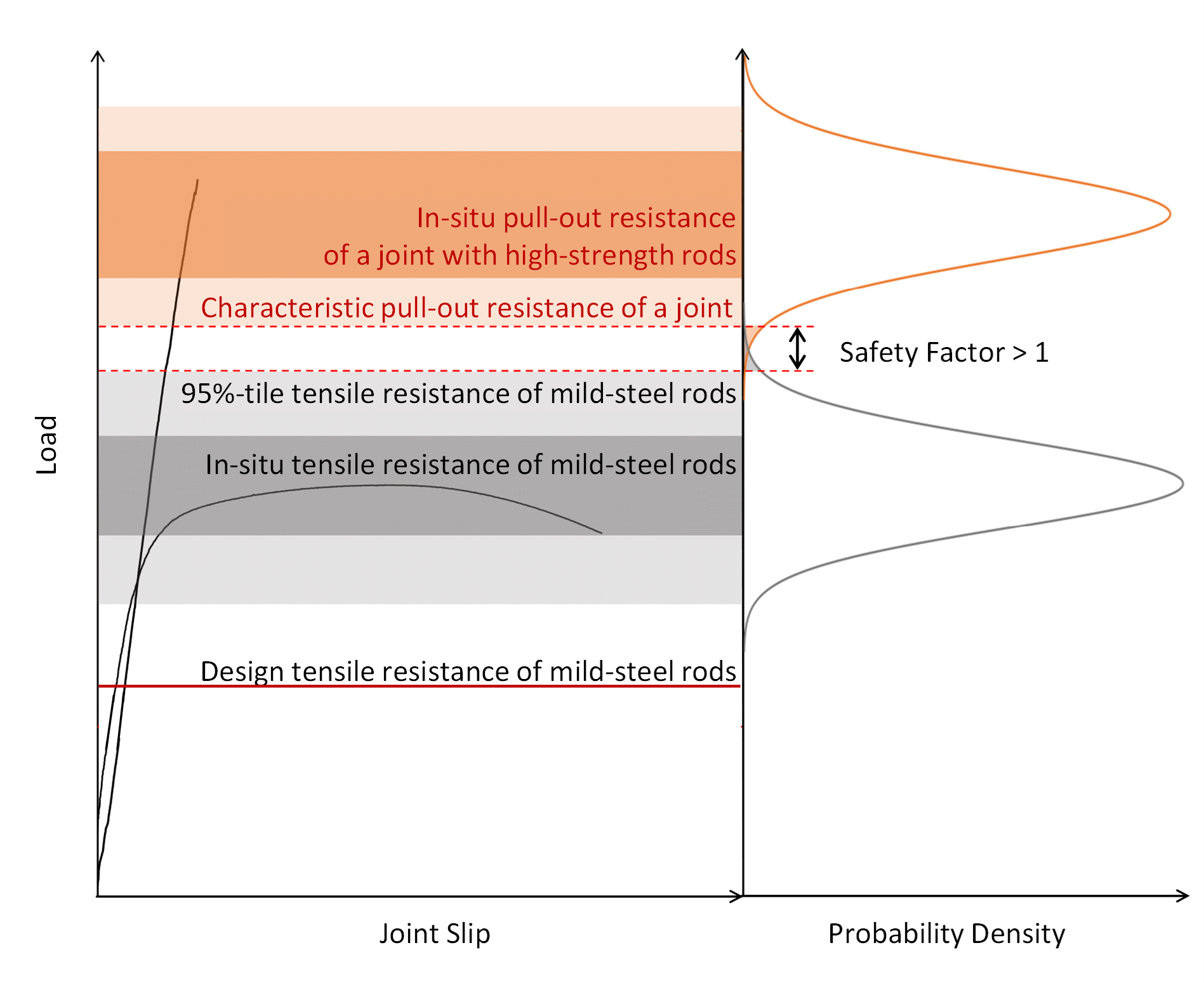

The fourth article was co-edited with Robert Jockwer from Chalmers University of Technology, (Sweden), Pedro Palma from EMPA (Switzerland) and Arthur Reboucas from Federal Institute of Education, Science and Technology of Rio Grande do Norte (IFRN), Brazil. It addresses the «Development of comprehensive testing procedures for high-performance bonded-in rods ».

Abstract: Bonded- or glued-in rods are a highly efficient fastening technology. The complexity of the interaction of different materials in the joint (adhesive, rod, and wood) and non-linear stress distribution along the bondline present special challenges for the precise characterisation of the strength and stiffness properties relevant for the design. The existing test standards and protocols specify only the bare minimum for the utilisation of these connections. The following aspects need a more detailed consideration in test specifications: rods in different wood-based products; impact of spacing and end/edge distances; group effects; quality assurance; fatigue; impact of environmental conditions, fire resistance, etc. In the paper, a detailed state-of-the-art regarding testing of bonded-in rods is given and the different aspects with need for further test development are discussed. Proposals are also made on how to better characterize experimentally the properties and behaviour bonded-in rods and on how to fully utilize their potential in design.

Graphic illustration of the design philosophy of joints with bonded-in rods.

BIOGRAPHY OF ALEXANNDER SALENIKOVICH

Dr. Salenikovich joined Laval University in 2003 with PhD in Forest Products at Virginia Tech (USA) after post-doctoral training at the Mississippi State University. Previously, he graduated with honours the Civil Engineering Faculty at Vyatka State University and worked as research engineer at the Center for Research, Engineering and Manufacture of Building Structures in Russia. He authored over 120 journal articles and conference papers and edited the Proceedings of the WCTE 2014. Professor Salenikovich teaches design of timber structures, mechanical properties of wood, and test methods. His research interests are focused on timber connections, seismic design, and testing procedures. He assumes leading positions in ASTM D07, ISO TC 218, ANSI/APA PRG 320 and active in other national and international technical committees.