Dynamic participation by the Corepan-Bois team at the 4th CRCBois Symposium!

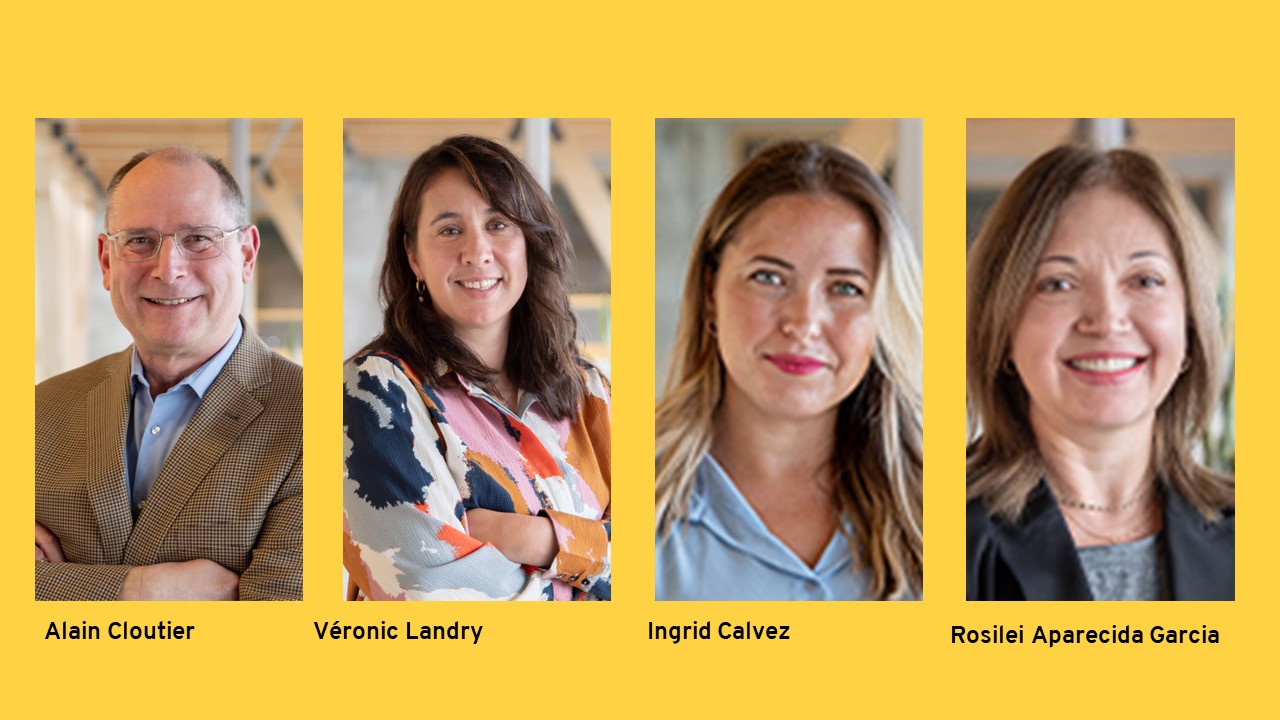

Four members of the Corepan-Bois team, including Professor Alain Cloutier, Professor Véronic Landry, and research professionals Ingrid Calvez and Rosilei Garcia, presented at the 4th symposium of the Canada Research Chair in Wood Valorization, Characterization, and Transformation (CRCBois), held on June 13, 2024, in LaSarre, Abitibi-Témiscamingue, Quebec. Congratulations on this achievement!

Organized by Professor Ahmed Koubaa (UQAT), holder of the CRCBois and associate member of the Renewable Materials Research Centre (CRMR), the symposium’s theme was « Bioproducts for a Circular Economy and a Sustainable Future ». The event showcased the results of CRCBois research projects and the solutions developed to valorize wood and its residues, aiming to create new bioproducts within the framework of sustainable development.

Alain Cloutier, full professor at the Faculty of Forestry, Geography and Geomatics (FFGG) and holder of the « Consortium de recherche sur les panneaux composites à base de bois (Corepan – Bois) », presented this major initiative. The project aims to contribute to innovation and scientific advancement in the field of wood-based composite panels, focusing on three areas of research: raw materials, processes and adhesives, and products and markets. This project addresses the main industry challenges in Canada.

Véronic Landry, full professor at FFGG and director of the CRMR, as well as holder of the NSERC\Canlak in Finishes for Interior Wood Products, presented the findings of her research on the the « valorization of whey ultrafiltration permeate for wood stabilization ».

During the symposium, Ingrid Calvez, research professional at Corepan-Bois, discussed the use of bio-based materials derived from industrial by-products in adhesives, presenting their advantages and disadvantages, as well as alternatives for low-emission or formaldehyde-free adhesives. In addition, Rosilei Garcia, also a research professional at Corepan-Bois, discussed « new advances, opportunities and challenges in the production of wood-based composite panels ».

Title of Alain Cloutier’s presentation: Le Consortium de recherche sur les panneaux composites à base de bois (Corepan-Bois): Valorization and recycling of wood.

Abstract. The Consortium de recherche sur les panneaux composites à base de bois (Corepan-Bois) commenced operations in spring 2023. It brings together researchers from Université Laval, Université du Québec en Abitibi-Témiscamingue, FPInnovations and Serex, as well as industrialists from Produits Forestiers Arbec, Sacopan, Tafisa and Uniboard. Over 30 graduate students are actively participating in this initiative. The consortium focuses on projects aimed at enhancing the value of wood in composite panels, improving manufacturing processes, and advancing panel and wood recycling technologies.

Title of Véronic Landry’s presentation: Valorization of whey ultrafiltration permeate for wood stabilization.

Abstract. Whey ultrafiltration permeate, a substantial by-product of the cheese industry in Quebec, currently lacks efficient recovery methods. This by-product can be utilized in wood treatment through esterification, enhancing wood’s dimensional stability and performance in outdoor environments. Several North American wood species underwent this treatment, with results detailing solution absorption, mass gain, dimensional stability, and mechanical performance. An evaluative analysis of the process’s potential and areas for enhancement will also be provided.

Title of Ingrid Calvez’s presentation: Innovative technologies and valorization of co-products for the development of bio-based adhesives applied to wood-based composite panels: state of the art.

Abstract. Traditional formaldehyde-based adhesives used in wood-based composite panels have raised environmental concerns due to their formaldehyde emissions. Over the past decade, the wood adhesives industry has undergone significant evolution, particularly in the development of bio-based alternatives. Various bio-based materials have been explored as substitutes for formaldehyde-based adhesives. Furthermore, there is a growing interest in circular economy practices, prompting innovative solutions utilizing industrial co-products and by-products. Industrial processes generate numerous co-products that can serve as renewable resources for producing eco-friendly materials, avoiding competition with food production. Many bio-based compounds, including saccharides, proteins, tannins, and lignocellulosic biomasses, have been investigated for developing bio-adhesives. In efforts to mitigate formaldehyde emissions, new hardeners and cross-linking agents are being developed to replace formaldehyde-based components. Additionally, alternative approaches such as binder-free panels are emerging. This presentation will highlight biobased materials sourced from industrial co-products, examining their benefits and drawbacks when integrated into adhesives. It will also explore alternative strategies for creating low-emission or formaldehyde-free adhesives, including the use of hardeners, bio-absorbents, and binderless panel technologies.

Title of Rosilei Garcia’s presentation: New advances, opportunities and challenges for the production of wood-based composite panels.

Abstract. An overview of the wood-based composite panel industry’s contribution to the sustainable development of the forestry sector in social, economic, and environmental terms will be provided, encompassing particleboard (PB), medium density fiberboard (MDF), and oriented strand board (OSB). Global production has reached record levels between 2021 and 2022, with PB, MDF, and OSB accounting for 66.7% of this production. The composition, applications, and conventional raw materials used in the manufacturing of these three panel types will be presented. Opportunities and challenges related to the use of new raw materials will also be discussed, including: (1) underutilized softwood species for OSB in Canada, (2) fast-growing species (e.g., willow) for PB and MDF, (3) logging residues, which are abundant but underutilized, (4) wood damaged by increasingly intense and frequent forest fires, and (5) post-consumer wood waste, the production of which is expected to rise due to growing demand for wood-based panels. A brief overview of materials used in the production of lightweight and multifunctional panels (e.g., fireproof, electromagnetically shielded, and with antibacterial surfaces) will also be provided.