Virtual tour of the Kruger Pavilion, Université Laval

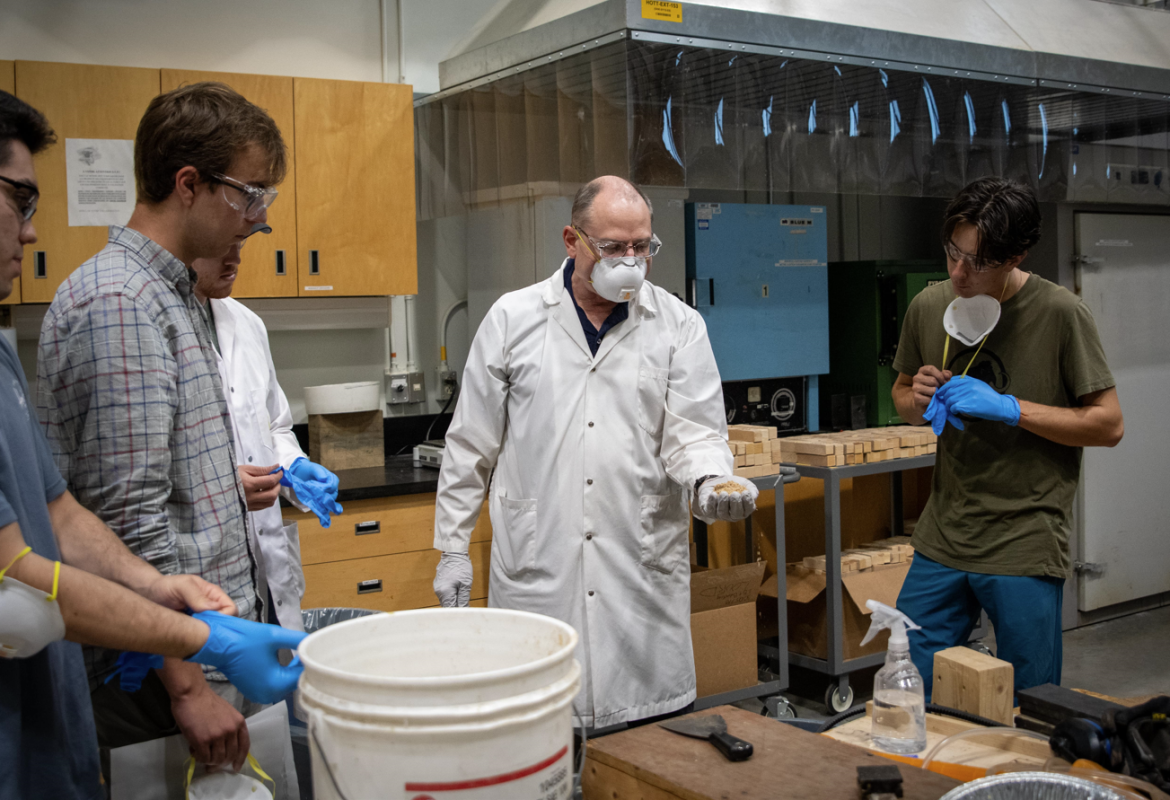

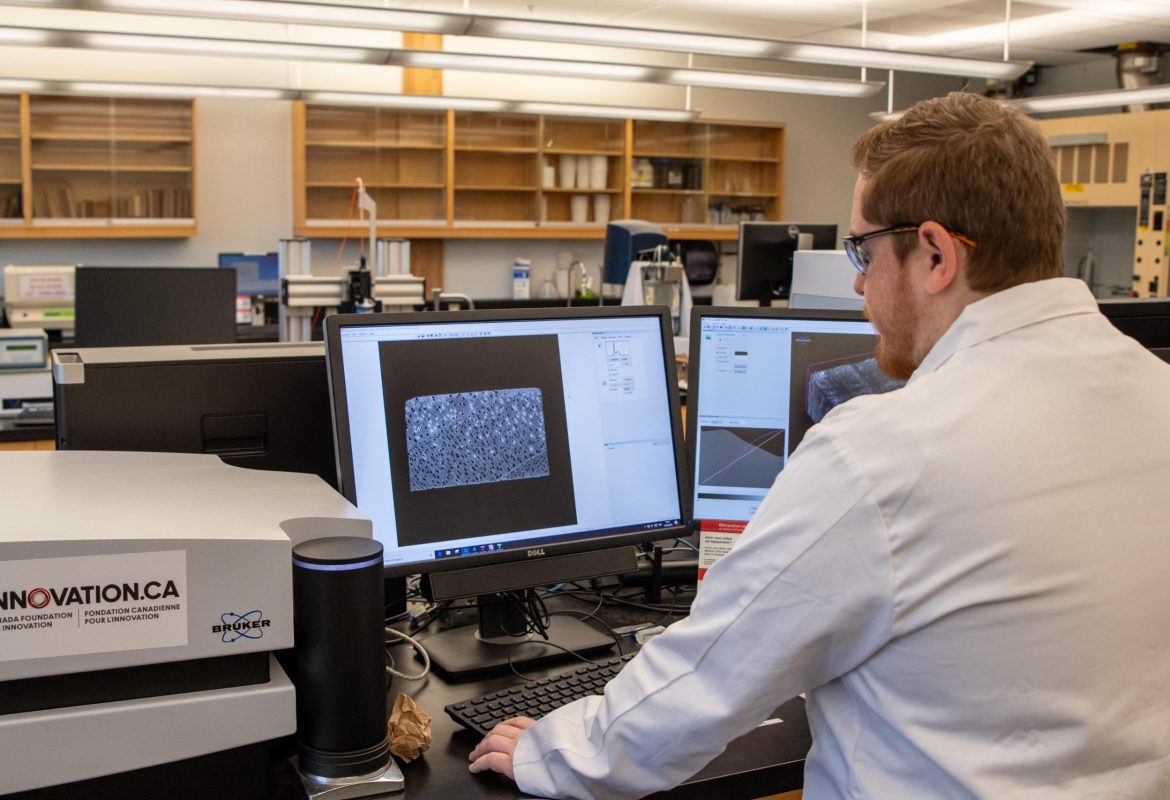

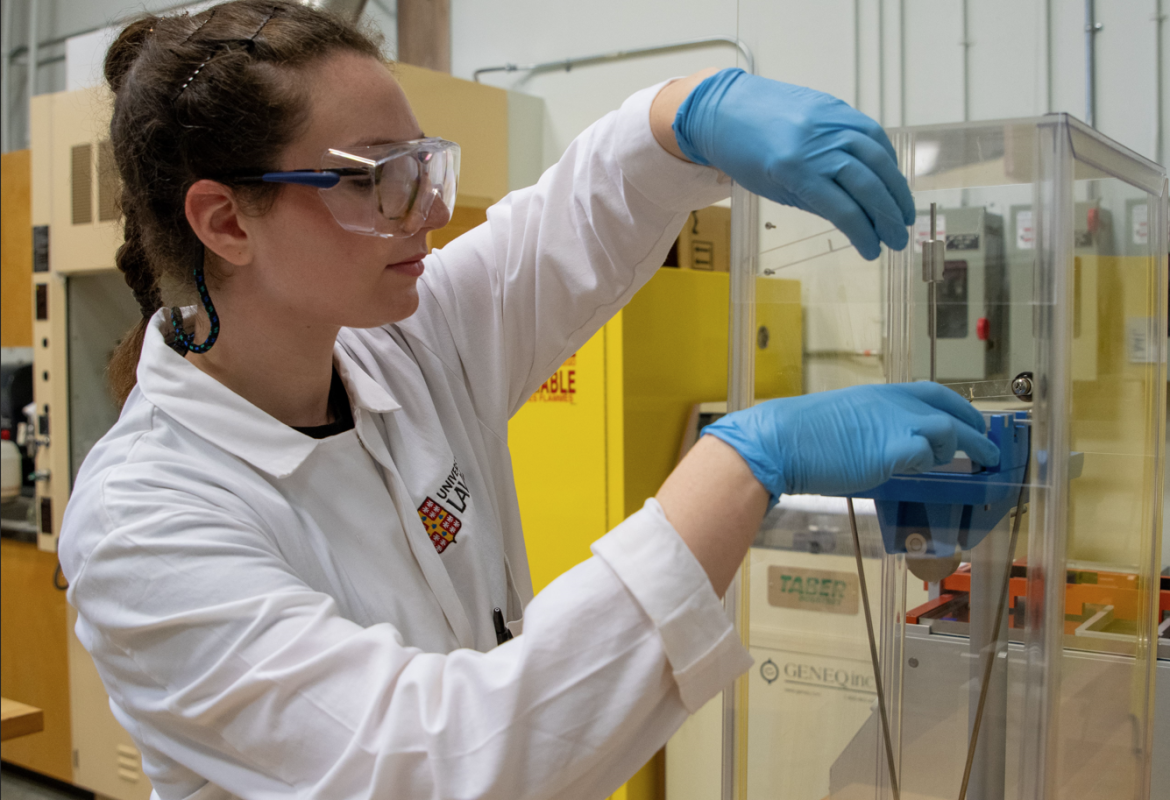

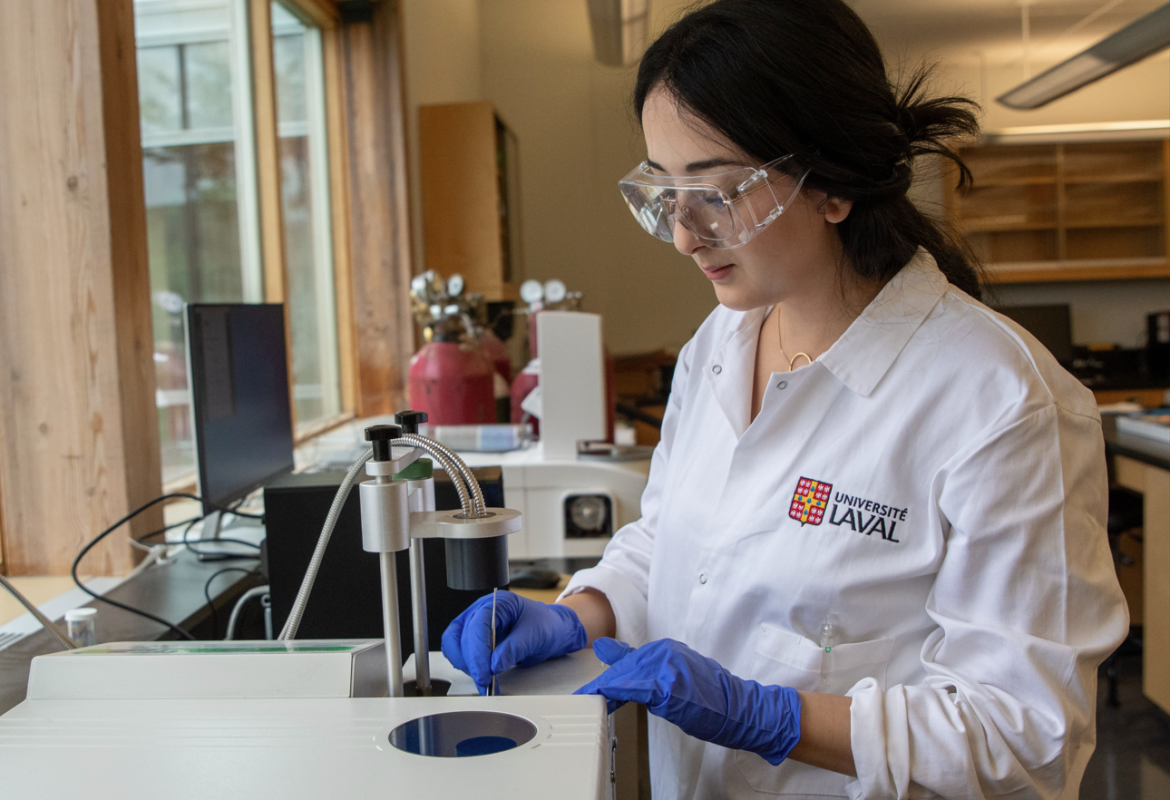

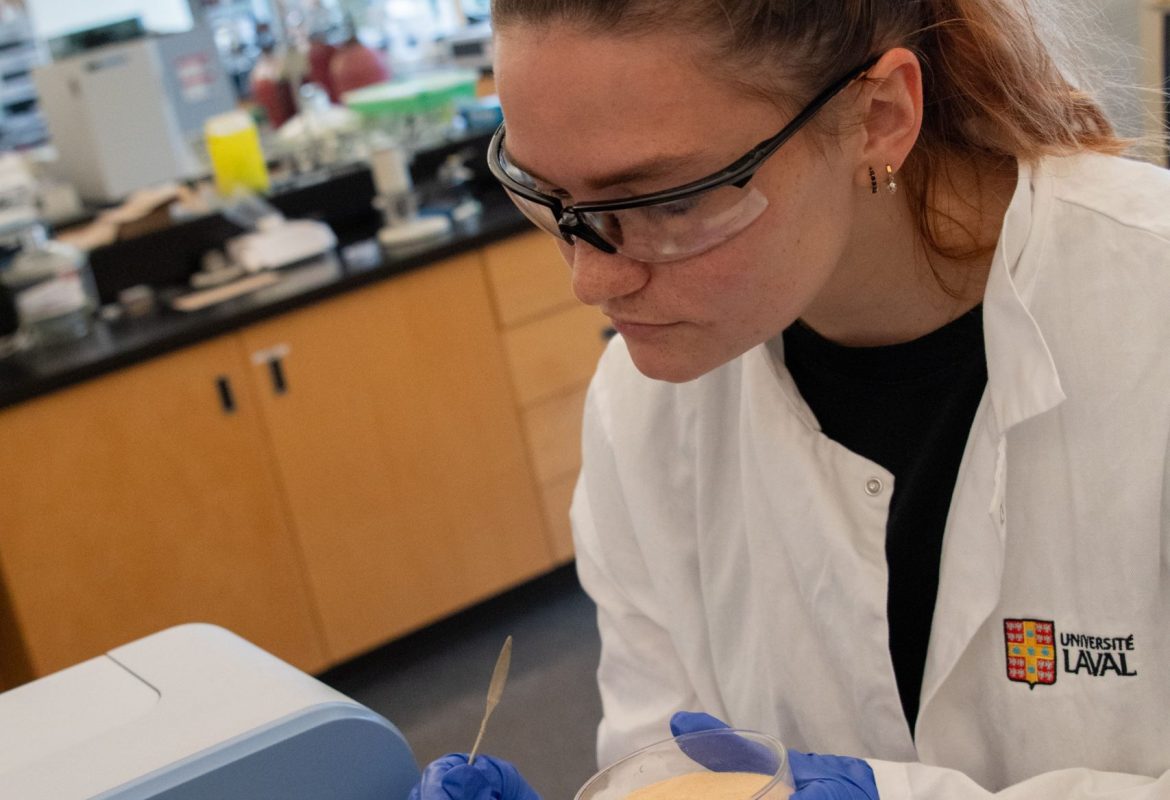

The majority of the Renewable Materials Research Centre (CRMR) laboratories at Laval University are located in the Gene-H.-Kruger building. This eco-friendly building, equipped with a bioclimatic environmental control system, is constructed almost entirely of wood and using local products was encouraged to benefit the regional economy and minimize pollution and transportation costs. In addition to conference rooms, classrooms and offices, there are ten workshops and eight laboratories where teaching and research are carried out in a number of fields including wood anatomy and physics, primary and secondary transformation, composite panels and polymer and adhesives chemistry. Futhermore, work on the implementation, characterization, modification and modeling of natural fibre-based composites, including expanded materials (foams), multilayer structures (sandwich) and recycling, under the supervision of Denis Rodrigue are carried out in the laboratories of the Chemical Engineering Department in the Adrien-Pouliot Building.

Overview of services

The CRMR is committed to exploring the potential of sustainable materials and offers a full range of external services to a diverse client base. These services encompass a wide range of activities and expertise, responding to the specific needs of academic researchers and various organisations (public and private) and industries seeking to promote research, development and innovation. Based on advanced research and innovative approaches, the centre offers valuable assistance in areas such as: the characterisation of raw materials, biopolymers and materials; the development of products, innovative systems and eco-responsible buildings; and the assessment of the behaviour, fire and environmental performance of innovative products and systems. In addition, the centre’s team of leading experts and researchers promotes innovation and collaboration, stimulating excellence and scientific and technological progress.

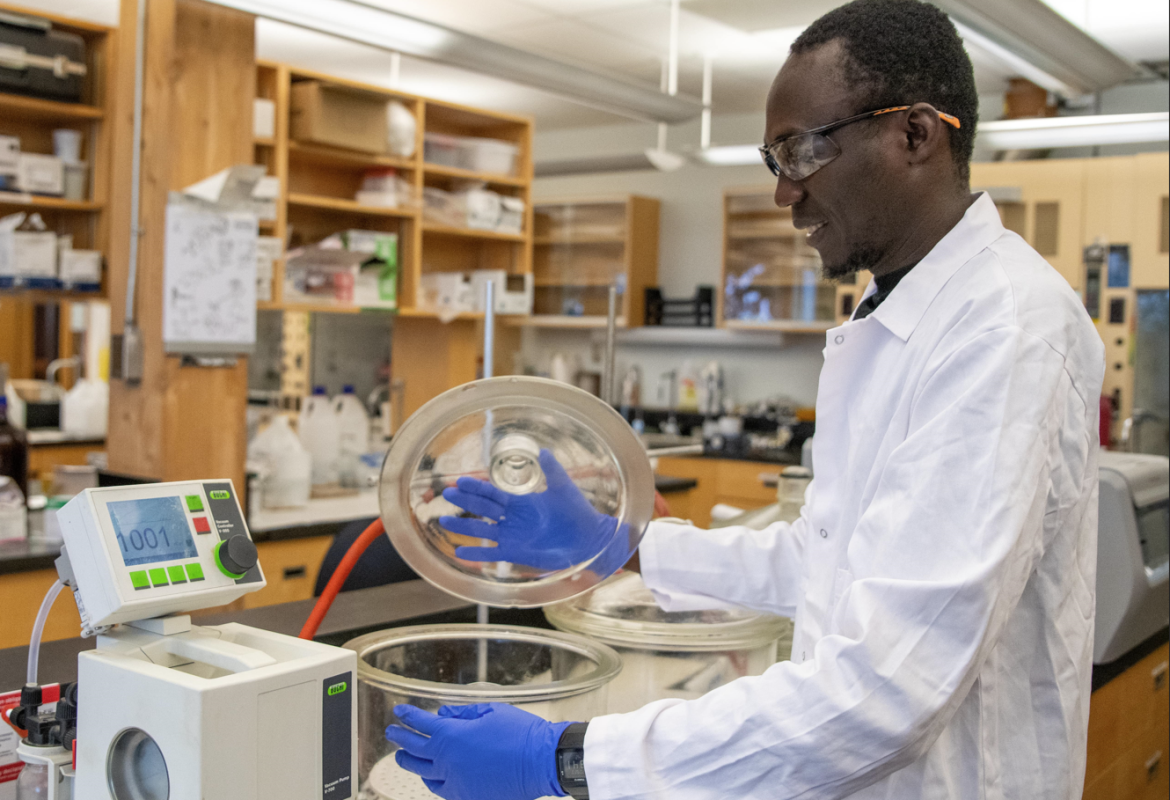

Characterisation of raw materials, biopolymers and materials

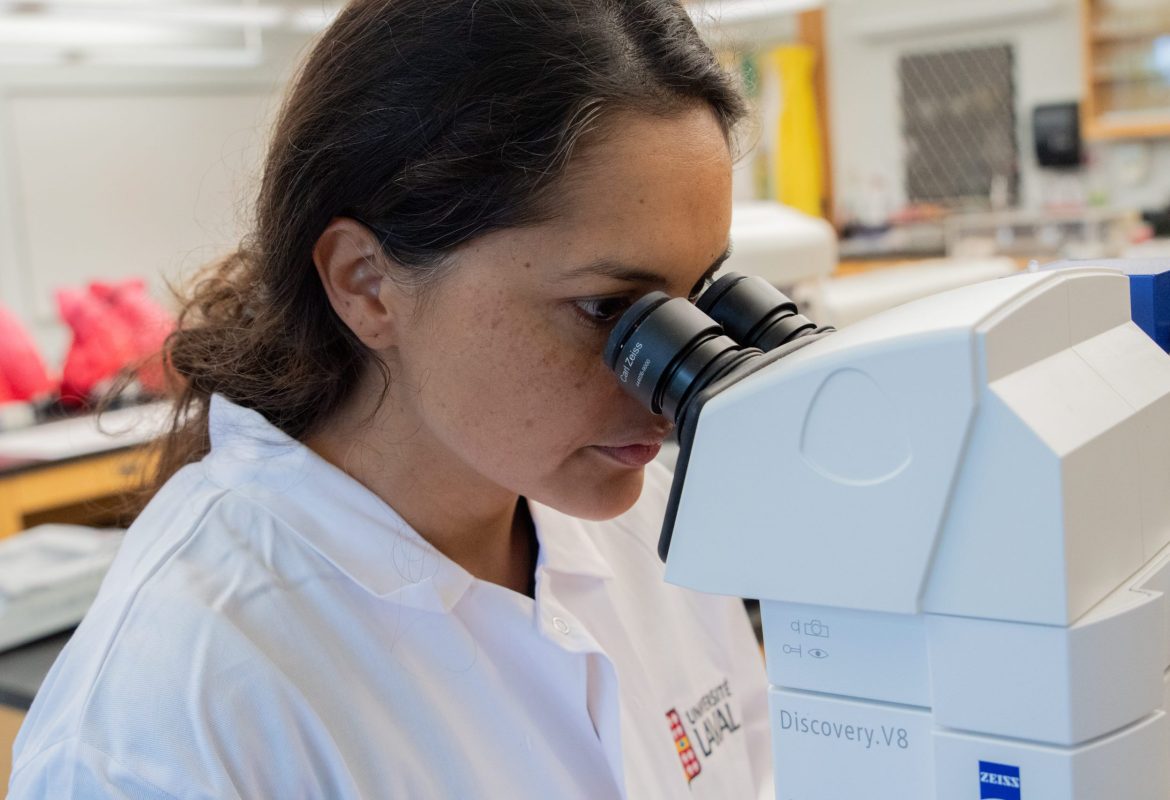

- Macroscopic and microscopic identification of wood species

- Physical properties (surface analysis, thermal conductivity, acoustic properties, X-ray densitometer, etc.)

- Mechanical properties (tension, compression, shear, bending, hardness, etc.)

- Chemical properties

- Fire performance

- Performance in accelerated aging

- Environmental performance of innovative products and systems

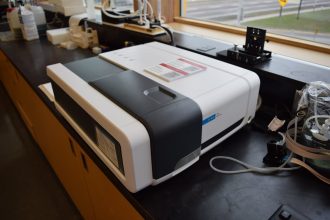

Cone calorimeter

Cone calorimeter

Studies the fire behaviour of small samples, with a surface area of 100×100 mm².

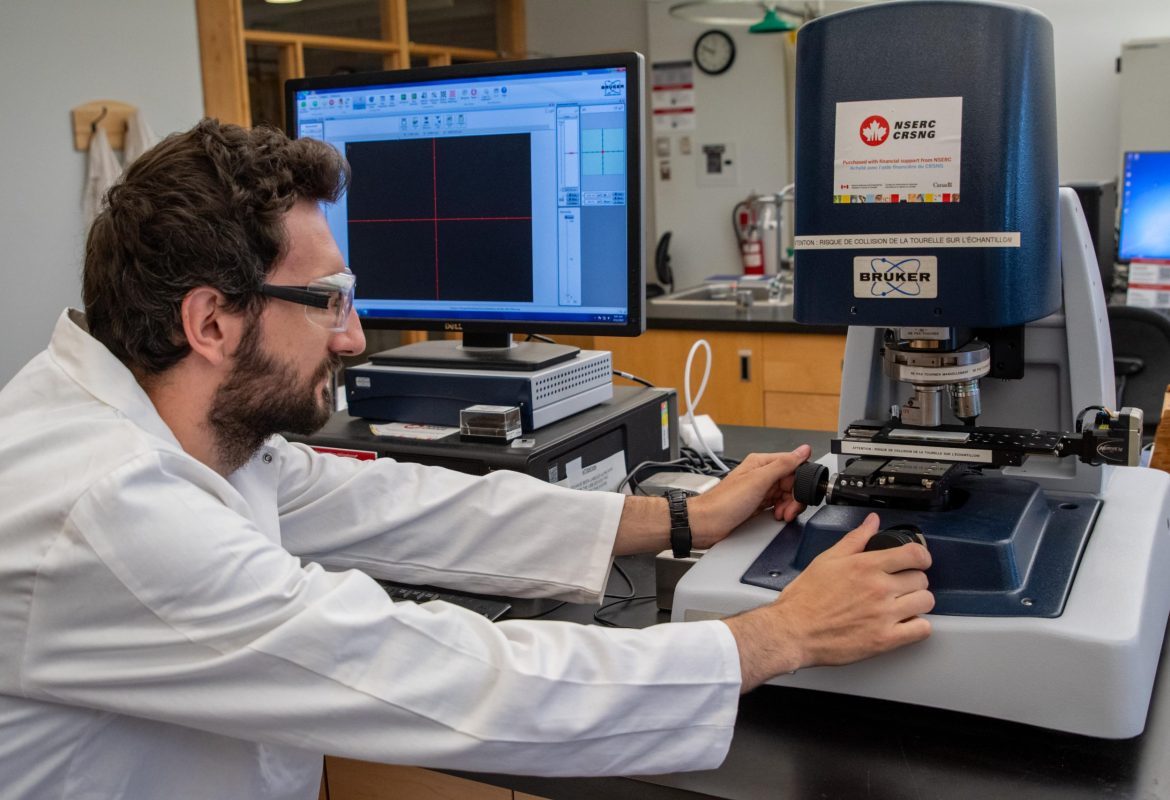

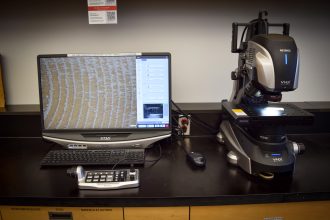

Micro Indentation Tester Anton Paar Step 300

Micro Indentation Tester Anton Paar Step 300

The Anton Paar Step 300 Micro-Indentation Tester is a highly advanced measuring instrument specially designed to accurately assess the mechanical properties of materials on a microscopic scale. Thanks to its advanced functionality and user-friendliness, this instrument has become an essential choice for characterising materials in various fields of research and industrial application. Parameters measured: hardness and modulus of elasticity, creep, relaxation, Hertz analysis, dynamic mechanical analysis (E‘, E’’, tan delta), stress-strain curve, fatigue.

Characterisation of construction systems

- Hygroscopic thermal performance and airtightness (e.g. light-frame wall and CLT wall)

- Mechanical performance (e.g. wall, beam, etc.)

- Large-scale fire performance (e.g. walls and ceilings)

Bending test bench

Bending test bench

Testing a piece of wood on the bench to determine its rigidity and breaking strength.

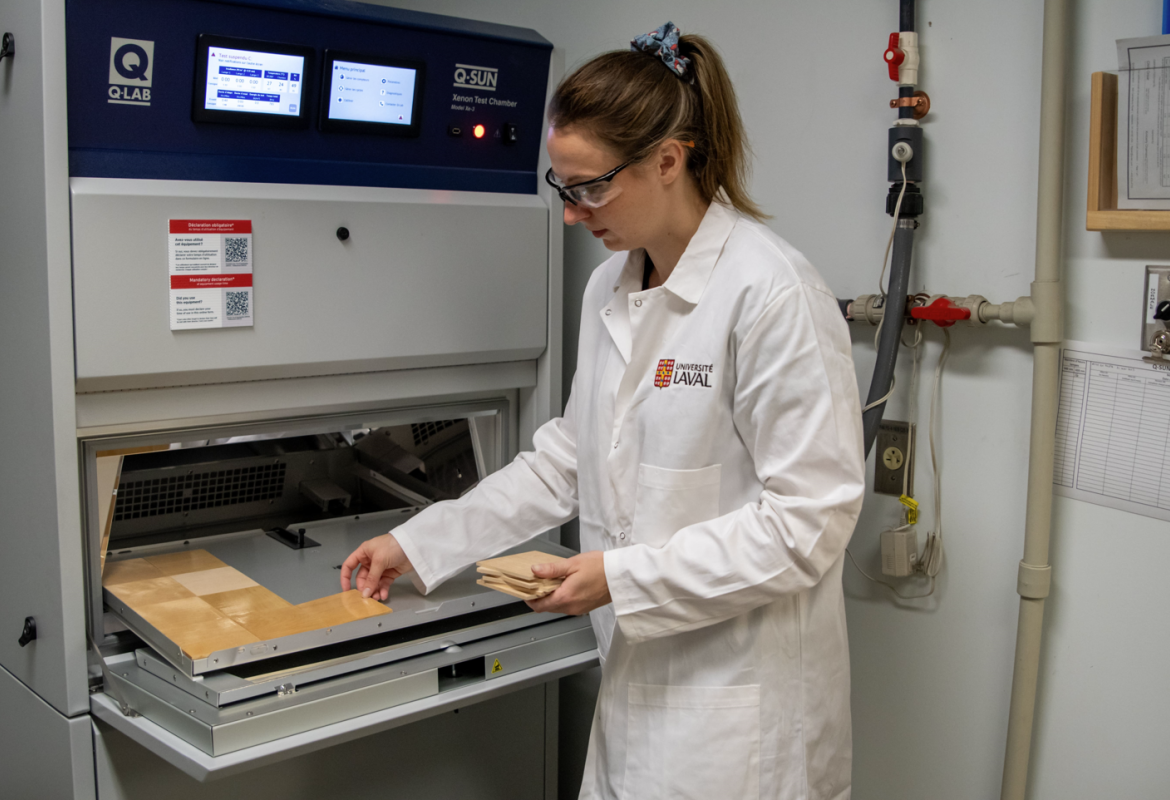

QUV and QSUN ageing apparatus

QUV and QSUN ageing apparatus

Simulation of accelerated ageing of a material by exposure to ultraviolet rays.

Studies of machining processes

- Rendering, sawing, planing, etc.

Numerically controlled 3-axis machining centre

Numerically controlled 3-axis machining centre

Used to machine wood pieces with complex shapes.

Services and partnerships

Internal:

- For support for undergraduate students and graduate projects at the CRMR and Université Laval, please contact: Benoit.St-Pierre@sbf.ulaval.ca.

- Support for CRMR projects carried out in partnership. To find out about the possibility of becoming a partner in a research initiative, please contact: veronic.landry@sbf.ulaval.ca.

External:

- Contracts and services: chercheur selon les champs d’expertise

- Equipment hire: Benoit.St-Pierre@sbf.ulaval.ca

We invite you to consult the list and a short description of the equipment available at the CRMR, the list of wood engineering research laboratories and the CRMR’s profile in the Canada Foundation for Innovation’s (CFI) research facility navigator below:

- Wood engineering research laboratories

- List of equipment available at the CRMR

- CRMR profile in the Canada Foundation for Innovation (CFI) research facilities navigator

If you have any questions about the equipment, please contact:

Benoit St-Pierre

Benoit St-Pierre

Specialist in charge of laboratories

Pavillon Gene-H. -Kruger – Local 1385

418 656-7385

benoit.st-pierre@sbf.ulaval.ca